See autonomous robotics in action. Built for safe and scalable production.

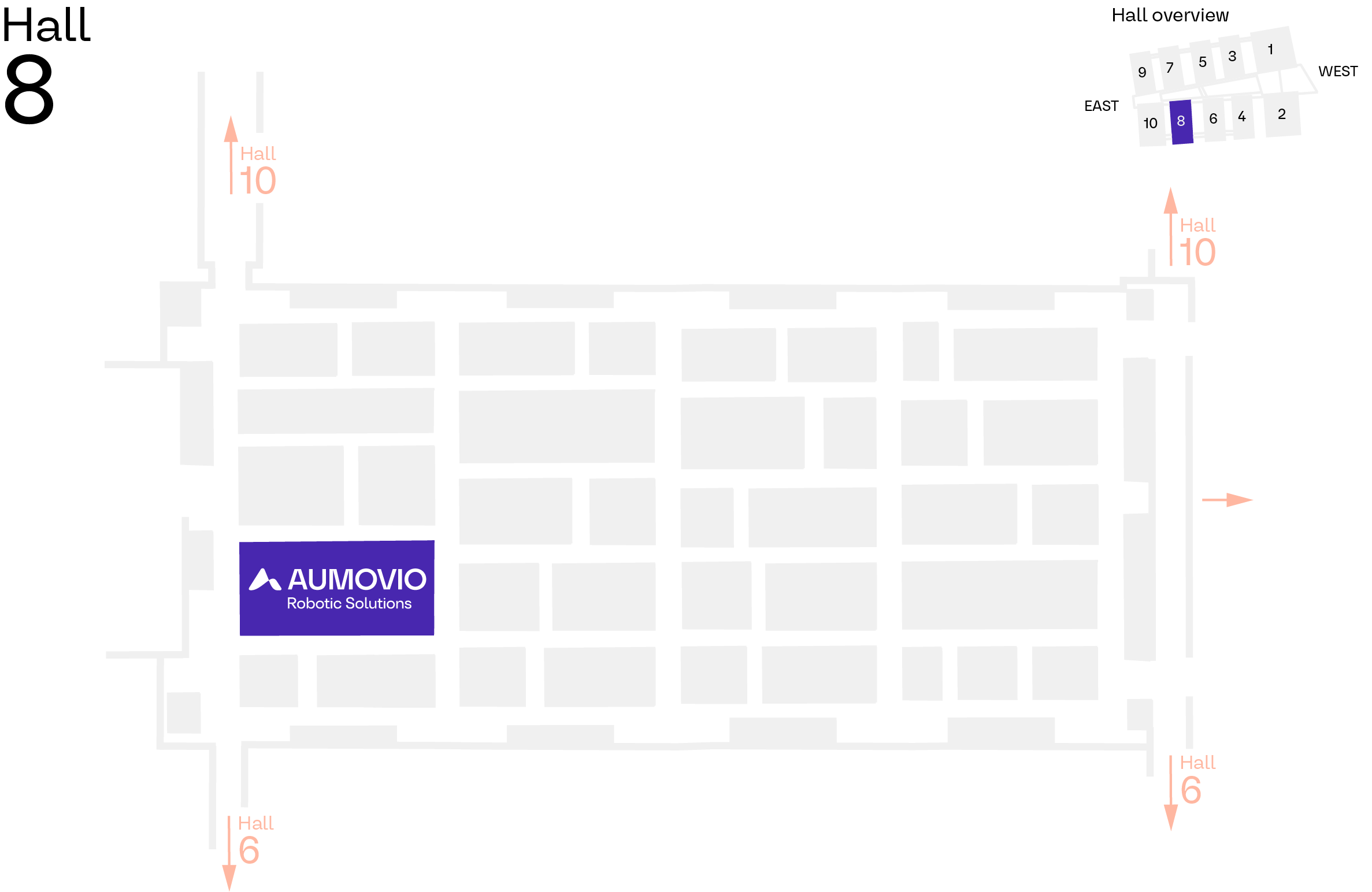

From March 24–26, 2026, visit AUMOVIO Robotic Solutions in Hall 8, Booth 8B61 at LogiMAT.

Together with KUKA, SYNAOS, and Wiferion, we present the second edition of the Interoperability Arena - larger, more international, and more immersive than ever.

On more than 600 m², discover how autonomous mobile robots (AMRs) from multiple manufacturers operate seamlessly within a shared intralogistics automation environment. Live demonstrations show crossing traffic flows, autonomous handovers, mixed fleets of AMRs and manual vehicles, shared charging infrastructure, and the interaction between mobile and stationary robots.

AUMOVIO Robotic Solutions presents the NXS 300, demonstrating how production-ready AMRs enable flexible, scalable, and reliable mixed-fleet operations for intralogistics and warehouse environments.

Experience interoperability in action.

Hall 8, Booth 8B61.

From small load carriers to heavy pallets, our autonomous mobile robots are engineered for fast, precise, and reliable intralogistics – supporting a wide range of payloads, including applications from 300 kg up to 1,200 kg, across production and warehouse environments.

Because every operation is different, AUMOVIO robots are designed to adapt to your processes and integrate seamlessly into existing layouts, workflows, and IT systems.

Our NXS 300 was built for fast and reliable transport of small load carriers and half pallets up to 300 kg. With its omnidirectional movement, advanced 360° perception, and intelligent navigation, it delivers exceptional precision and safety – even in narrow aisles or dynamic environments.

Thanks to its VDA 5050‑compatible integration and multiple configuration options, it adapts seamlessly to your processes and grows with your intralogistics needs.

It autonomously transports pallets, boxes, and bulk loads with payloads ranging from 600 kg up to 1,200 kg between production and warehouse areas. Supporting both free and fixed pickup and drop-off points, including conveyor integration, it helps reduce manual handling and improve overall process efficiency.