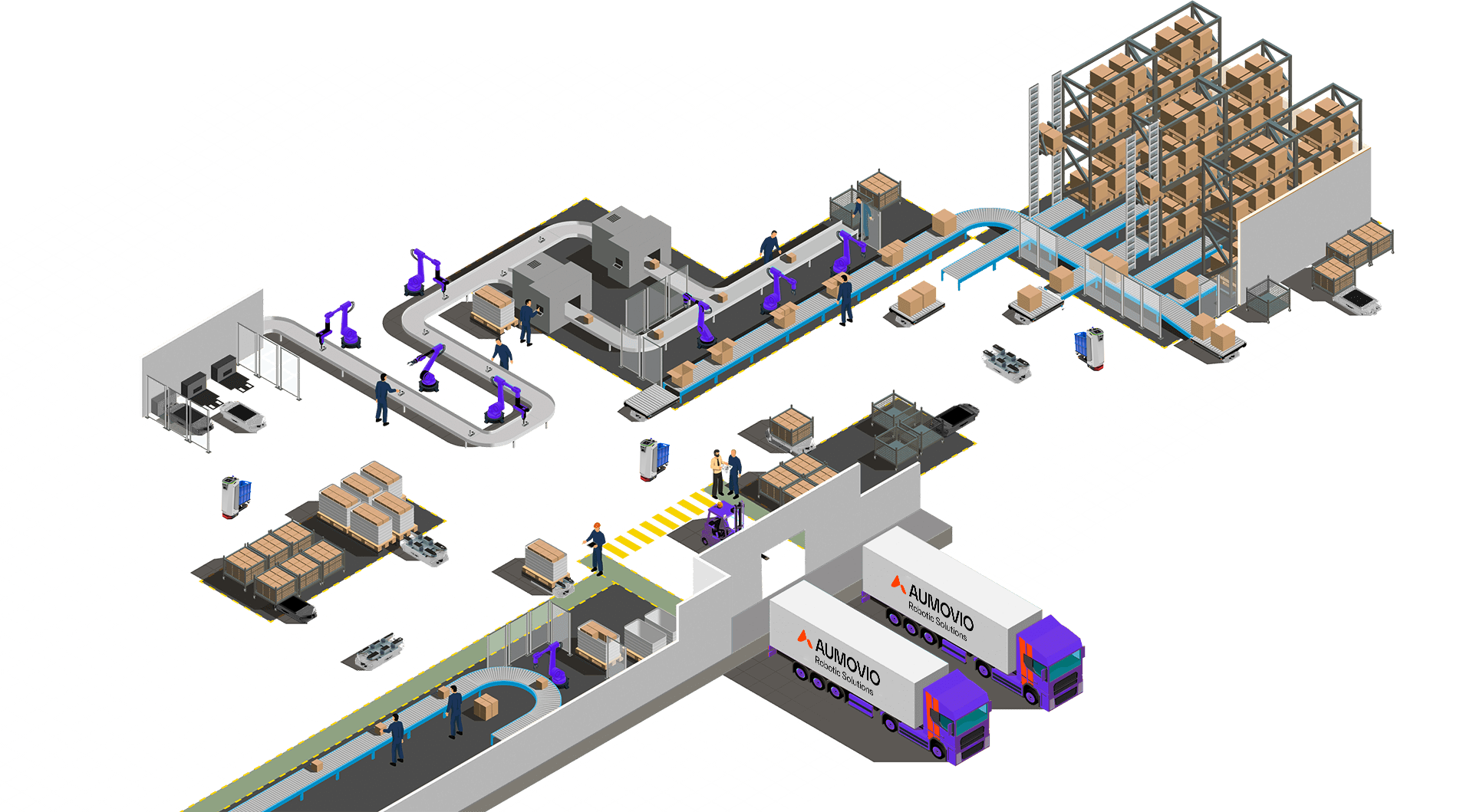

AMRs for smart intralogistics.

A robot alone won’t solve your challenges. But when fully integrated into your processes, the possibilities are limitless. At AUMOVIO Robotic Solutions – formerly Continental Mobile Robots – we help companies transform intralogistics into a competitive advantage.

Discover how autonomous material flows, intelligent fleet master control, and our 24/7 end-to-end support can optimize your operations.

We are your trusted partner in building scalable, safe, and future-ready intralogistics solutions.

Request a consultation today and discover our solutions in action.

Contact us

We build long-term, trust-based partnerships. While our products are highly technical, it’s our personal interaction that creates real value.

Every intralogistics process is different. That’s why our AMR portfolio offers the right solution for every use case – from small parts to heavy pallets.

Maximum payload: 600 kg

Maximum payload: 1200 kg

Top roller modules from our partner ROEQ

Maximum payload: 600 kg | 1200 kg

Maximum payload: 300 kg

For transporting small load carriers

Use case: Small load carrier, half pallets

At the core of every AMR fleet is our fleet master control – intelligent, scalable, and easy to use. The intuitive interface allows you to add and customize routes in just a few clicks. Real-time maps and dashboards give you full visibility of vehicles, shipments, and charging status. With seamless integration into your existing systems, you can always keep your fleet running at peak performance.

Our Autonomous Mobile Robots not only comply with the VDA 5050 standard – they are already proven in daily operations at customer sites and go beyond it. With VDA 5050+, our AMRs are natively integrated into leading fleet management control (FMC) systems, without the need for additional bridges or middleware. We collaborate daily with our FMC partners to jointly develop new features that extend far beyond the standard. At the same time, we remain open to customer-specific requirements and are ready to integrate with further FMCs – simply reach out to us. This way, we ensure true interoperability, seamless operation of mixed fleets, and future-ready intralogistics solutions.

The fleet master control seamlessly integrates all autonomous mobile robots into your intralogistics and coordinates every transport order. It automatically assigns the most efficient vehicle based on distance and battery status, manages charging, and controls traffic flow for smooth operations. Routes can be created and adjusted in just a few clicks. With real-time tracking, interactive maps, and dashboards, you gain full visibility and control of your AMR fleet at all times.

Dimensions |

Length × width × height |

1,455 mm × 630 mm × 225 mm |

Performance Characteristics |

Rotation diameters |

260 cm |

Power Supply |

Battery type |

Li-Ion / 48 V / 47 Ah |

Environment |

Ambient temperature |

5°C – 40°C |

Safety |

Sensors and safety functions |

4 × LIDAR Laser Scanner, 2 × 3D camera, |

Connections |

Wi-Fi link |

2.4 GHz and 5 GHz supported, 2 antennas |

Length × width × height

Weight

Ground clearance

1,455 mm × 630 mm × 225 mm

240 kg

28 mm

Rotation diameters

Navigation

Position accuracy

260 cm

Autonomous

Fine positioning: ± 5 mm

Battery type

Charging current

Loading strategy

Loading time

Li-Ion / 48 V / 47 Ah

25 A / max. 30 A

Opportunity Charging

1:20 h

Ambient temperature

Humidity

5°C – 40°C

10 % – 90 % @ 39°C, noncondensing

Sensors and safety functions

Detection range

Safety standards for Industrial Vehicles

IP Code

4 × LIDAR Laser Scanner, 2 × 3D camera,

4 × emergency stop button, 2 × red light, optional: signal tower

360°

MRL 2006 / 42 / EG, EMV RL 2014 / 30 / EU, RED RL 2014 / 53 / EU,

EN ISO 13849-1:2015, EN ISO 13849-2:2012, EN 1175:2020, CE,

ISO 3691-4:2020

IP20

Wi-Fi link

Ultra-wideband (UWB) ready

Integration

Manual control

2.4 GHz and 5 GHz supported, 2 antennas

Yes

VDA 5050 compatible

USB controller, control via laptop computer or mobile phone

Our autonomous mobile robots keep your processes running smoothly and reliably. And if support is needed, we are here for you – anytime. With 24/7 service and assistance, our experts ensure maximum uptime and fast response whenever challenges arise.

We identify where automation with AMRs creates the most value in your processes.

We set up your AMRs, train your team, and ensure you can run the robots and the fleet independently.

As processes evolve, we adapt your AMRs to keep performance high – today and tomorrow.